“Egyptian authorities suggest that the Ever Given container ship that ran aground blocking the Suez Canal could have been due to human error.” Such headlines attributing serious accidents to “human error” are remarkably common following nearly every serious incident. But what does that tell us? Other than acts of God, aren’t all accidents the result of some form of human error? Don’t all humans commit errors from time to time? Have we confused proximate cause for root cause? Should finding someone to blame for human error be the end of the story or (better) the beginning?

Unless your company is doing a very poor job of employment screening, none of your workers show up on the job wanting to make mistakes and errors that could get them, or their coworkers injured or killed. Most workers much prefer to be productive and recognized for their positive contributions. Of course, we all, myself very much included, make mistakes. Some of those mistakes could be considered careless, or even stupid. But does labeling such mistakes human error, and then finding someone to blame for them, contribute to organizational learning and improvement? I think not. Blaming workers for accidents is nearly always shortsighted and counterproductive. What makes me say this?

The Problem with Blame

- Too often when the proximate cause “mistake” is found, and the guilty party or parties are identified it’s the end of the story. Workers are disciplined, and/or retrained and new rules or procedures are added. These fixes, however, ignore root cause and do little more than alienate the workforce and make the work more complex.

- When incident investigations conclude with human error as the cause you have stopped learning. The root cause context and system deficiencies that set the stage for the incident go unaddressed. If your investigation is focused on individual behaviors rather than the system overall sustainable improvement is simply not possible. Blaming individuals for unwanted events is both simple, and in our nature, but human error is inevitable and very rarely a conscious choice. Blame corrects nothing but leaves system weaknesses in place.

- Blame based on hindsight is fundamentally unfair and kills workforce trust so important to continuous safety improvement. Too often blame is assigned for long tolerated practices that finally and unexpectedly resulted in an incident. Blame for the unexpected consequences of common practice, however, sends a terrible message to your workers who may well be “guilty” of the same practices and even rewarded for doing them. No rational worker does things to purposely cause harm. More commonly they do what they believe are in the interest of getting the job done as quickly and efficiently as possible.

- Corrective actions based on blame are almost always limited to the individuals involved and/or company-wide behavioral modification initiatives. Many of these actions are expensive, overly complicate the work and alienate the workers. Despite the expense and effort expended, corrective actions based on blame do nothing to promote lasting improvement as they completely fail to address root causes.

It’s easy and often tempting to assign blame after an accident. In rare cases (e.g., unsafe work for personal gain, drug use…) it is probably justified. But blaming the workers for incidents (i.e., consequences) gains you very little and can have far reaching negative consequences; consequences that cost you money as well as the trust and engagement of your workers. It’s generally not the workers that need fixing but the system and culture that need improvement. If you think human error is the end of the story you haven’t looked hard enough.

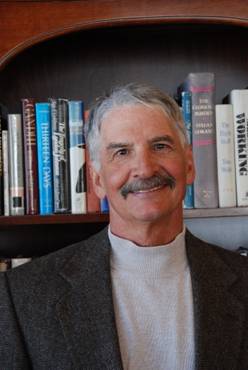

Author Bio

Mr. Loud’s over 40 years of safety experience includes 15 years with the Tennessee Valley Authority (TVA) where he served as the supervisor of Safety and Loss Control for a large commercial nuclear facility and later as manager of the corporate nuclear safety oversight body for all three of TVA’s nuclear sites. At Los Alamos National Laboratory he headed the independent assessment organization responsible for safety, health, environmental protection, and security oversight of all laboratory operations.

Mr. Loud is a regular presenter at national and international safety conferences. He is the author of numerous papers and articles. Mr. Loud is a Certified Safety Professional (CSP), and a retired Certified Hazardous Materials Manager (CHMM). He holds a BBA from the University of Memphis, an MS in Environmental Science from the University of Oklahoma and an MPH in Occupational Health and Safety from the University of Tennessee.