Why reconcile

Monitoring chemical usage and stock within an industrial or research setting is critical to maintain proper safety and compliance standards within the lab environments. Reconciliation helps to verify that the quantities of chemicals used in lab experiments have been accounted for. Comparing and matching the actual physical stock of chemicals within the storage area to the recorded inventory in a tracking system will minimize the risk of using expired stock and alert the lab personnel of low or misplaced inventory. Early detection of such discrepancies is necessary to ensure accuracy and consistency of material usage, data, and experiment results.

RECONCILIATION CHALLENGES

In an academia setting, lack of certain standard procedures in the laboratories can make it difficult for the researchers and scientists to reconcile materials usage and stock availability. An inefficient or outdated paper-based inventory tracking system can be time consuming in recording, organizing, managing, and reporting chemical usage and disposal of hazardous waste with a high likelihood of human error. For scientists working on complex experiments, missing or expired stock can cause delays in productivity and efficiency. Chemical reconciliation presents unique challenges in the manufacturing industry as well, a recent visit to an aerospace facility revealed a complex chemical landscape that their chemical safety team had been navigating for a while. The current process relies on manual check in and check out of chemicals using spreadsheets resulting in inconsistent entries and incorrect stock quantities. As a result, chemical materials are often overordered in excess due to inefficient reconciliation methods leading to substantial financial setbacks and reporting errors.

Leverage barcode and rfid for precise inventory management

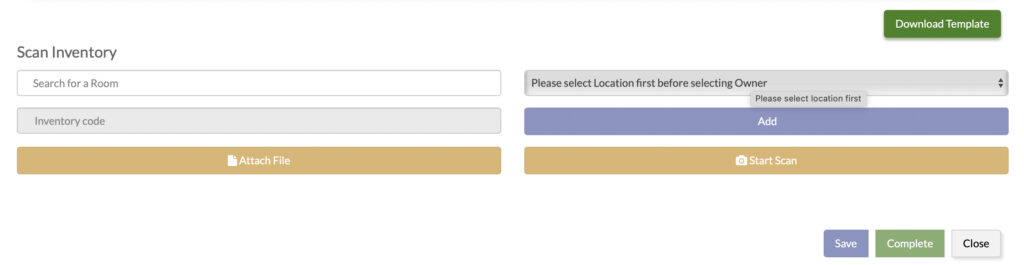

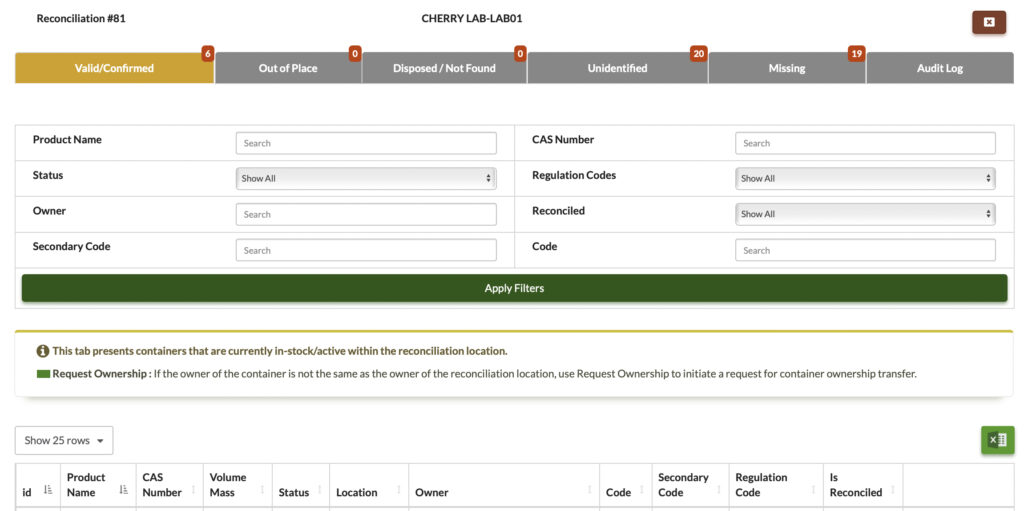

With the aim of reducing these challenges and automating certain tasks, SafetyStratus has developed a reconciliation process that integrated seamlessly with their existing inventory tracking system. By utilizing a barcode system and RFID (Radio Frequency Identification) technology to enhance inventory management, SafetyStratus has made a significant impact in enhancing efficiency, especially in industries with complex chemical use and storage needs where data needs to be updated in real time. This innovation ensures better compliance and effective handling of chemicals.

Here are a few key benefits of how RFID can be applied to reconciliation:

Data Collection & Reduce Human Error

- Functionality: When barcode or RFID tags are attached to chemicals, scanning can be done in real time during check in and check out without the need to perform a manual entry.

Benefits: Items in the inventory get updated instantly leaving no room for human error.

Inventory Tracking and Monitoring

- Functionality: Continuous monitoring of usage and disposal of chemicals.

- Benefits: Reduces the risk of lost or misplaced items thereby ensuring accurate reporting.

Automate Reconciliation process

- Functionality: RFID technology provides an automatic match with the physical items corresponding to the inventory records in a database. When an item is scanned, the system will display the location and stock usage to highlight any discrepancies between the actual and recorded quantities.

- Benefits: There is considerable reduction in the time spent doing a manual reconciliation.

Reporting and Compliance

- Functionality: RFID scanning can track hazardous material usage in compliance with regulations and generate accurate reports.

- Benefits: Ensure compliance and safety standard maintenance.

Conclusion

In conclusion, the custom-built solution has proven to be a transformative step in improving the reconciliation process for inventory management particularly in industries that require real time data tracking and accuracy. By revolutionizing reconciliation, SafetyStratus helps our clients streamline inventory tracking, minimize human errors, increase productivity, and reduce risks in chemical handling. Ultimately, managing chemicals with great precision and maintaining regulatory standards, SafetyStratus has positioned itself as a leader in the environmental, health and safety industry sector.

AUTHOR BIO:-

Kavita Kanukolanu blends her technical expertise with a deep interest in safety and systems thinking. With a background in Computer Science and experience leading complex IT projects, she brings a structured yet thoughtful perspective to her writing.

She writes to bridge the gap between technology and safety—translating intricate concepts into clear, engaging content. Passionate about continuous learning and purposeful communication, Kavita explores how innovation, compliance, and smart workflows shape safer, more efficient environments across industries.