You are out on the job making sure everyone is safe and doing their designed task as expected. You, as the contractor, are responsible for the job and the safety of your team. But what about the subcontractor? Of course, they are your responsibility for the quality of their work and the safety they provide for themselves and your team.

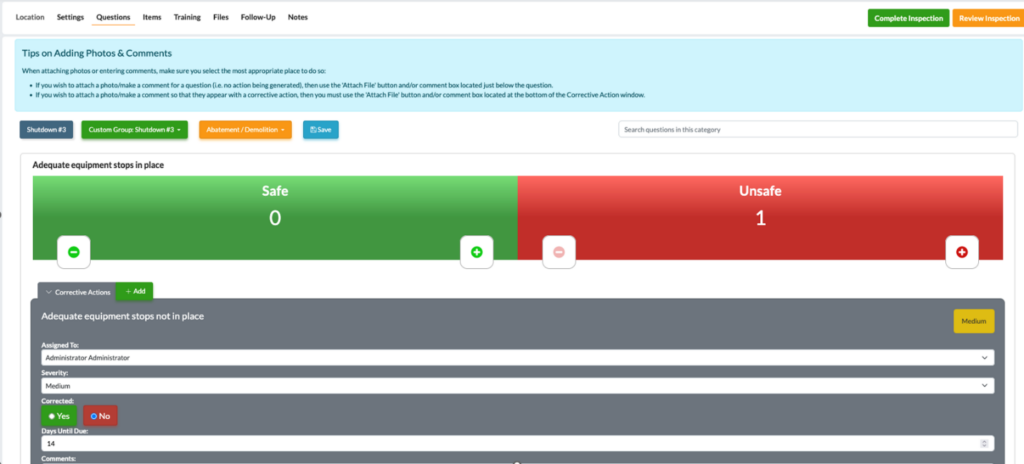

You inspect your team regularly, checking to ensure safety is always their main priority, and you have your regular inspections with your team included, and you know everyone on the project and who to assign Corrective Actions (Issues that need to be addressed to keep everyone safe). But for the next two weeks, you have ABC welding specialists onsite working. Are you tracking how safe it is to have this subcontractor on your project? How do you note when they are being safe and keeping your team safe? Or worse, unsafe? Is this someone you want to invite back on the next job because you have the confidence and the data to back up that this team assisting in your project has a safety-first mindset?

Real confidence in a subcontractor’s safety is not a “gut” feeling based on what you see as you pass the workers; it’s derived from data collected during inspections. Inspections that may not be completed by you. Others can assist in collecting this data by having assigned inspectors complete inspections so it’s not all on you to determine the team’s safety. Data that can be reviewed and analyzed as a whole and add confidence to your decision to allow this team on your job or to keep them away for the safety of your team.

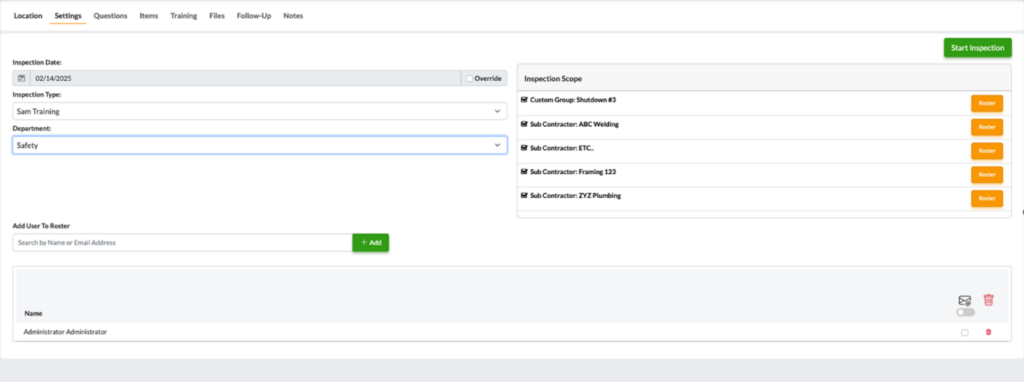

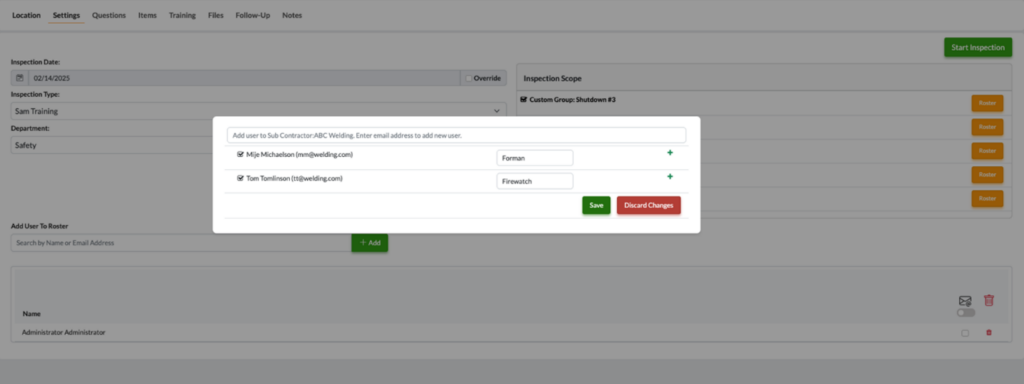

We use SAM (Safety Assurance Methodology) to inspect a large project with many different moving parts. First, you have the Project as a whole. We will call that Plant Shutdown #3 for this example. This is your company, which has its own employee list with their own responsible roles to which they can be assigned Corrective Actions. Then you have subcontractors, each of which has their own employee list, which would need to address any safety issues found. Your team could then inspect the project, and as you are inspecting, you can seamlessly transition between subcontractors as needed without the need to conduct separate inspections for each.

An example project could be:

Project: Shutdown #3

sub: ABC Welding

Foreman: Mike Michaelson

Fire watch: Tom Tomlinson

Sub: ZYZ Plumbing

Foreman: Mr. Plummer

Helper: Helpy Helperson

Sub: Framing 123

Foreman: Frank Framer

Helper: Freddy Framer

Sub: ETC…

Forman: ETC…

Once a few inspections are complete, you can access summary reports based on project, inspector, location, etc. If the data is collected, you can narrow it down based on that data to ensure the team is consistently performing at optimal safety.

There is nothing more important than your team’s safety. The only way to truly ensure safety is a constant is through inspections, which provide you with the necessary data to make informed on job site changes that need to be made for adding a simple safety upgrade to your project as a whole, all the way to possible not inviting that subcontractor back to ensure your team safety. Either way, you will have data to justify your decisions and needs.

AUTHOR BIO:-

Randy Langston has built a career defined by adaptability and growth. From hands-on work in construction and welding to managing the greens of a golf course, he eventually pivoted into the tech industry.

After completing a technical degree, he joined SafetyStratus as a Technical Support Agent, where his dedication and expertise led him to his current role as Technical Support Manager. With a diverse background and a passion for problem-solving, Randy brings a unique perspective to the tech world.